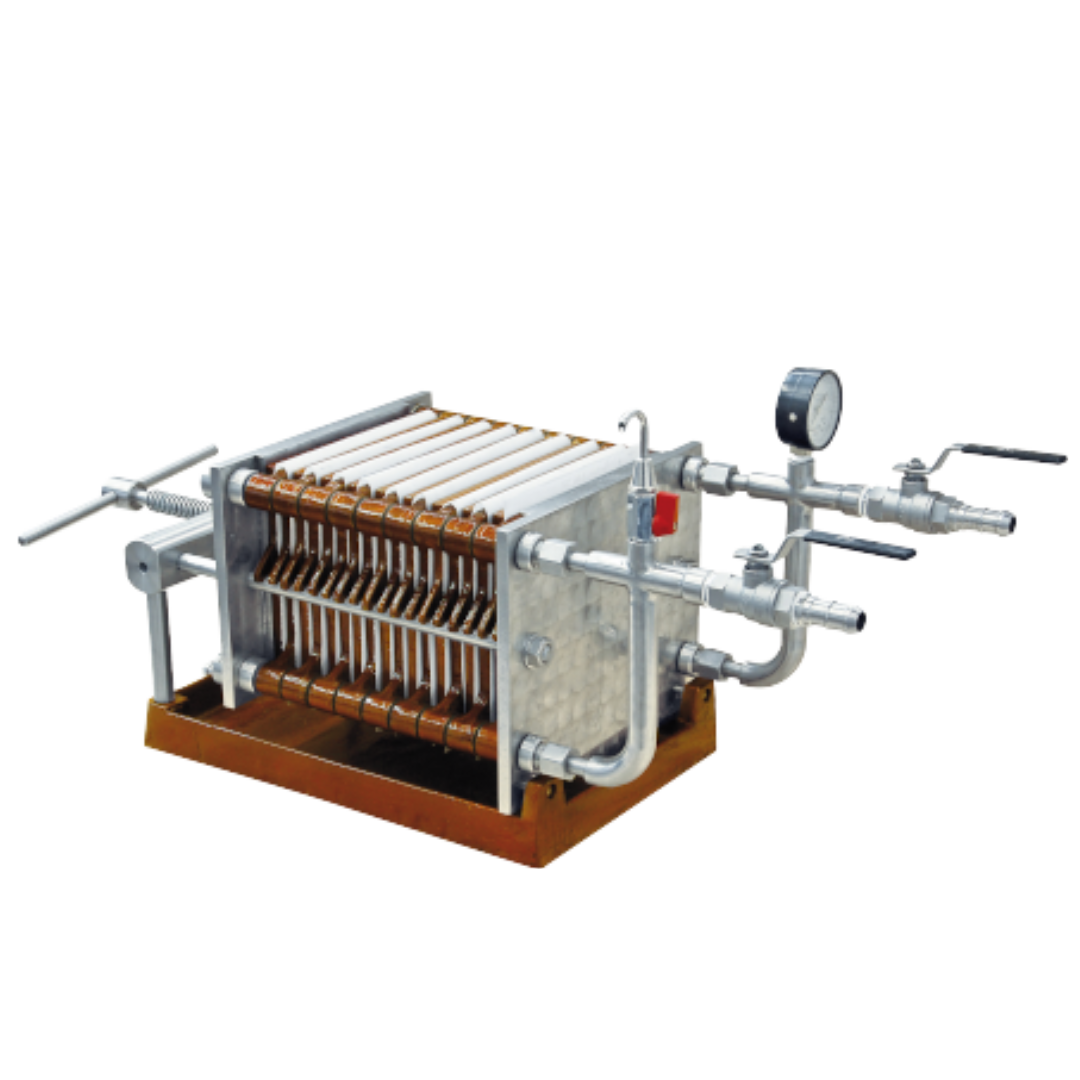

Filter presses

Filter press D18

++ HIGHEST PRECISION MADE FROM STAINLESS STEEL – FOR PERFECT PRESSING RESULTS ++

Efficient filtration: Up to 10 liters per hour

16 chambers: For precise oil cleaning with small throughput

Compact design: Ideal for farms and direct marketing

Robust & hygienic: stainless steel components – Made in Germany

Performance range: 0.04 – 0.18 MPa working pressure (max. 0.4 MPa)

Easy operation: Manual clamping device & pressure display

Clean end product: Clear, filtered oils ready for bottling

6-year warranty: For maximum operational reliability

Price on request

Available from stock

information

The D18 filter press is a compact and powerful solution for the fine filtration of cold-pressed vegetable oil . With 16 chambers and a filtration area of 0.64 m², it is ideal for small to medium-sized oil production plants where high filtration quality and process reliability are essential.

With a working pressure range of 0.04 to 0.18 MPa and a maximum permissible pressure of 0.4 MPa, it is versatile and offers stable results with oils of varying viscosity. The filter press achieves a throughput of up to 10 liters per hour and is ideal as a complement to an Oilex oil press.

The construction of high-quality stainless steel components , combined with a robust base plate, makes the D18 not only hygienic but also durable and low-maintenance. It is operated manually via a sturdy clamping device. An integrated pressure gauge ensures easy monitoring of the pressure gradient during the filtration process.

Whether in direct marketing, in the laboratory, or in small professional operations – the D18 delivers clear, clean oils and is therefore an important component for consistent quality production.

What are the areas of application for oil presses?

As a manufacturer, we offer you every oil press and oil mill in various sizes for small processing quantities of 3 kg per hour up to large processing quantities of several tons per hour (depending on the seed) for the food production, animal feed production, pharmaceutical and cosmetic industries as well as for protein extraction.

Of course, we also design and manufacture a professional oil press on our own lathe and milling machine, completely customized to your specifications for cold pressing your oils, even with water cooling if required.

What are the possible uses?

You can use our oil presses to produce fresh and healthy oils from a wide variety of kernels, nuts, and seeds – free from any additives and natural, such as:

Chia seeds, peanuts, rosehip seeds, prickly pear, hemp seeds, hazelnuts, coconut flakes, pumpkin seeds, linseed, almonds, poppy seeds, rapeseed, mustard seeds, sesame, sunflower seeds, grape seeds, walnuts and many more that you can find here.

Each oil press is fully assembled, so you can start producing right away. For cleaning, they can be disassembled and reassembled in just a few steps. You can use each oil press to produce your own vegetable oil and cold-pressed oil.

With our filter presses, you can then filter the oils. The oil cakes can then be used, for example, for animal feed or ground into flour.

Let us advise you without obligation on which oil press or machine for cold-pressed oil extraction from kernels, seeds, and nuts is suitable for your purposes, so that you buy the oil press that perfectly suits your production process.

How do oil presses differ from each other?

The screw press can be designed as a perforated strainer screw press, a strainer-rod screw press, or a strainer-disk screw press. A perforated strainer screw press has a perforated press cylinder. The oil exits through oil outlet channels on the wall of the screw press. In the strainer-rod screw press, strainer rods are arranged at fixed intervals. The vegetable oil exits from the gaps between the strainer rods.

What are the differences?

There are manual oil presses. These take a little longer and require more effort. Therefore, electric oil presses have understandably become very popular in recent years, as they offer significantly greater ease of use. They have a higher performance, making them perfect for producing larger quantities of oil, especially if you want to produce large quantities commercially or industrially. We offer exclusively electric oil presses due to their high level of convenience and efficiency.

There are significant differences between oil presses in terms of functionality and features. High-quality models are equipped with various accessories, making them easy to use as a walnut oil press, for example. To ensure the electric oil press is optimally suited for walnuts, the pressing process can be optimally adjusted to the required temperature. The variable temperature ensures that no important nutrients in nuts and seeds are destroyed.

Which foods can be processed with the Oilex oil press models?

used for oil production.

The Oilex oil press can also be used to produce nut oil. Nuts are also known for their particularly strong aroma and often impart a distinctive flavor to the foods in which the finished oil is used. Many types of nuts can be processed in the oil press. In addition to hazelnuts, walnuts are also very suitable.

The oil press can be easily cleaned after cleaning. The oil presses we offer produce a high-quality press cake in pellet form, which is then very easy to process. The press cake can be used, for example, in the production of animal feed.

When choosing a good oil press, quality should always be considered. It's important that the press achieves a high oil yield so that the seeds can be pressed as gently and efficiently as possible.

Our alternative

Efficient and durable solutions for filter pressing a wide variety of seeds. Made in Germany for the highest quality and maximum oil yield.

Details

- Filter chambers: 20–80 pieces – depending on the model

- Filtration area: 3.20–12.80 m²

- Capacity: 20–80 liters per hour – ideal for small to large oil batches

- Working pressure: 0.15 MPa (max. 0.6 MPa)

- Stainless steel fittings & precise pressure monitoring

- Mobile & flexible – thanks to a stable chassis

- Robust industrial quality – for professional oil filtration

- 6-year warranty on all components

Contact us

We are here for you – quickly and easily.

Contact information

Oilpressparts GmbH & Co. KG

Gewerbering 13

41372 Niederkrüchten

Germany

Opening hours

Mon – Thurs: 8:30 am – 4:30 pm

Friday: 8:30 – 14:00

Get in Touch

office@oilpressparts.com

+49 2163 8883626